The Undiscovered Elegance of Furnace Condensate Traps

In the realm of home comfort, there's a quiet elegance to the components that work diligently behind the scenes. One such element, often overlooked yet undeniably essential, is the furnace condensate trap. Like a perfectly tailored detail on a bespoke garment, the condensate trap plays a vital role in maintaining the smooth operation and longevity of a high-efficiency furnace.

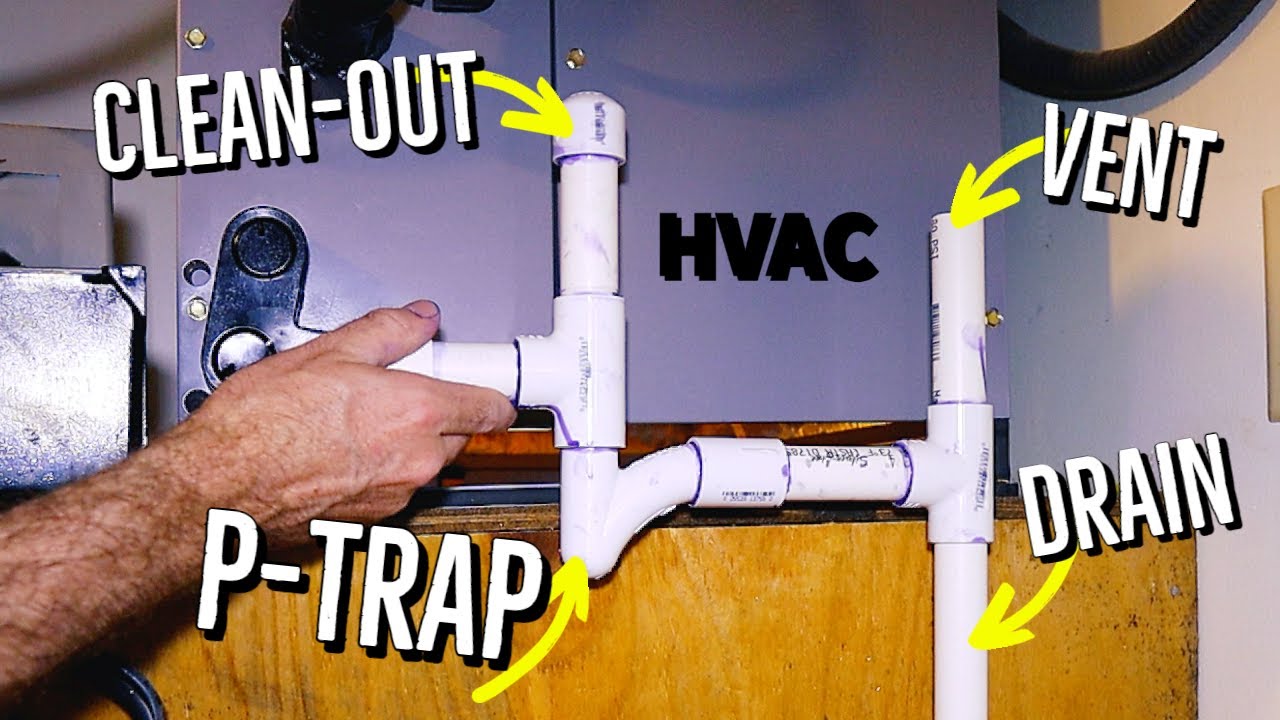

Consider the condensate trap as the unsung hero of your heating system. Its purpose is simple yet crucial: to collect and remove the condensation produced during the combustion process. High-efficiency furnaces extract so much heat from the exhaust gases that water vapor condenses into liquid form. This condensate, if left unmanaged, can corrode vital furnace components and lead to premature system failure.

The history of the condensate trap is intertwined with the development of high-efficiency furnaces. As manufacturers sought to maximize energy utilization, they designed furnaces that extracted more heat, leading to increased condensation. This necessitated a mechanism to handle the byproduct – the condensate trap was born. Its design has evolved over time, from simple gravity-fed traps to more sophisticated pump-assisted systems, reflecting the ongoing quest for efficiency and reliability.

The importance of a properly functioning condensate trap cannot be overstated. It protects the furnace from corrosion, preventing costly repairs and extending its lifespan. Furthermore, a well-maintained condensate line prevents water damage to the surrounding area, safeguarding your home from potential leaks and mold growth. A clogged condensate trap can lead to furnace shutdown, leaving you without heat, particularly inconvenient during the colder months.

One of the most common issues associated with condensate traps is clogging. Dust, debris, and even algae can accumulate in the trap and line, restricting the flow of condensate. This blockage can lead to a backup, triggering a safety switch that shuts down the furnace. Regular maintenance, including cleaning the trap and flushing the line, is essential to prevent such problems. One simple example is ensuring the trap's inlet and outlet pipes are clear of obstructions.

One benefit of a properly functioning condensate removal system is the increased efficiency of your furnace. By efficiently removing condensate, the system can operate at its peak performance, reducing energy consumption and lowering utility bills. Another advantage is the prolonged lifespan of the furnace. By preventing corrosion, the condensate trap helps protect vital components, extending the life of your heating system and saving you money on premature replacements. Finally, a well-maintained condensate system contributes to a healthier indoor environment by preventing the growth of mold and mildew, which can thrive in damp conditions.

An action plan for maintaining your condensate trap should include regular inspections, typically every three months. Check for visible clogs, leaks, and proper drainage. Annually, flush the condensate line with a mixture of vinegar and water to remove any buildup. If you notice any persistent issues, consult a qualified HVAC technician for professional assistance.

Advantages and Disadvantages of Condensate Traps

| Advantages | Disadvantages |

|---|---|

| Increased furnace efficiency | Potential for clogs and leaks |

| Extended furnace lifespan | Requires regular maintenance |

| Improved indoor air quality | Can be noisy if not properly installed |

Best Practices for Condensate Trap Maintenance:

1. Regularly inspect the trap for clogs and leaks.

2. Flush the condensate line annually with a vinegar and water solution.

3. Ensure proper trap and line inclination for efficient drainage.

4. Install a condensate pump if gravity drainage is not feasible.

5. Schedule professional HVAC maintenance annually.

FAQs:

1. What is a condensate trap? - A device that collects and removes condensation from a high-efficiency furnace.

2. Why is it important? - Prevents corrosion, extends furnace life, and improves indoor air quality.

3. How often should I clean it? - Inspect every three months, flush annually.

4. What causes clogs? - Dust, debris, algae.

5. What are the signs of a clogged trap? - Water leaks, furnace shutdown.

6. Can I clean it myself? - Yes, for basic cleaning and flushing.

7. When should I call a professional? - For persistent issues or complex repairs.

8. How can I prevent clogs? - Regular maintenance and annual flushing.

Tips and Tricks: Use a wet/dry vacuum to clear clogs, consider installing a filter on the condensate line, document your maintenance schedule.

In conclusion, the furnace condensate trap, though seemingly a small component, plays an indispensable role in the overall performance and longevity of your heating system. Its proper function ensures efficient operation, prevents costly repairs, and contributes to a healthier home environment. By understanding its importance and implementing a consistent maintenance plan, you can protect your investment and enjoy the warmth and comfort provided by your high-efficiency furnace for years to come. Don't underestimate the power of this unassuming device – its impact on your home comfort is significant. Take the time to familiarize yourself with its operation and maintenance needs; it's a small effort that yields substantial rewards. Investing in the upkeep of your condensate trap is an investment in the long-term health and efficiency of your heating system, ensuring a cozy and comfortable home for years to come. Just like a well-chosen accessory completes an outfit, the condensate trap completes the efficient and reliable operation of your furnace.

Anime planet not working troubleshooting guide

Avoid cashiers check scams targeting wells fargo customers

Cultivating financial wellness for your little ones