Understanding Held Open Normally Closed Limit Switches

Imagine a simple mechanism that ensures a door stays shut unless a specific action occurs. This seemingly basic function is often achieved using a normally closed, held open limit switch. These unassuming devices play a crucial role in various automated systems, quietly ensuring safety and proper operation.

A normally closed, held open limit switch, sometimes called a NC-HO switch, is a type of electrical switch that remains closed in its default state. An external force, like a lever or actuator, holds it open. When this force is removed, the switch returns to its closed position. Understanding this fundamental principle is key to grasping the broader applications of these switches.

Think of it like a spring-loaded door closer. The spring keeps the door closed until someone pushes it open and holds it there. As soon as they let go, the spring pulls the door shut. Similarly, a held open normally closed limit switch maintains a closed circuit until something holds it open, breaking the circuit.

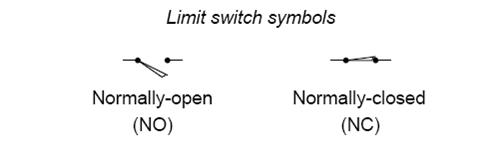

The symbol for a normally closed, held open limit switch generally depicts a normally closed switch with an indicator showing the held open condition. This standardized representation helps technicians and engineers quickly identify and understand the switch's function within a circuit diagram. Variations in the symbol might exist depending on the specific standard being used, but the core concept remains the same.

These switches are essential components in many safety and control systems. They’re frequently found in industrial machinery, elevators, garage doors, and even household appliances. Their reliability and simple operation make them invaluable for ensuring specific actions happen only when intended.

The history of limit switches is intertwined with the development of automation and electrical control systems. Early versions were simple mechanical contraptions, evolving over time into the sophisticated electromechanical devices we use today. The need for reliable and precise control in increasingly complex machinery spurred the development of specialized switches like the normally closed, held open type.

One primary concern with these switches is ensuring their proper adjustment and maintenance. Misalignment or mechanical wear can lead to malfunctions, potentially compromising safety. Regular inspection and adjustment are crucial to maintain reliable operation.

A key advantage of normally closed, held open limit switches is their fail-safe nature. In the event of a power failure or control system malfunction, the switch automatically returns to its closed state, often triggering a safety mechanism. For example, in an elevator, a normally closed, held open limit switch might be used to prevent the doors from opening between floors. If power fails, the switch closes, ensuring the doors remain shut.

Another benefit is their adaptability to various control systems. They can be easily integrated into circuits that monitor position, presence, or other conditions. This flexibility makes them suitable for a wide range of applications, from simple safety interlocks to complex automated processes.

Furthermore, their relatively simple construction and operation make them easy to install and troubleshoot. This contributes to lower maintenance costs and reduced downtime in industrial settings.

Troubleshooting a malfunctioning normally closed, held open limit switch often involves checking for mechanical obstructions, verifying wiring connections, and testing the switch's continuity. A multimeter can be used to measure the resistance across the switch terminals to determine if it is functioning correctly.

Best practices for implementation include selecting the appropriate switch for the specific application, ensuring proper mounting and alignment, and protecting the switch from environmental factors like moisture and extreme temperatures.

Real-world examples include using these switches in industrial conveyor systems to detect the presence of items, in safety interlocks on machinery to prevent operation when guards are open, and in access control systems to monitor door positions.

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Fail-safe operation | Susceptibility to mechanical wear |

| Adaptable to various control systems | Potential for misalignment |

| Easy installation and troubleshooting | Requires regular inspection and maintenance |

Frequently asked questions might include inquiries about the switch's wiring, symbol variations, common troubleshooting techniques, and suitable applications.

In conclusion, the normally closed, held open limit switch is a critical component in countless applications, quietly ensuring safety and reliable operation. Understanding its function, symbol, and best practices for implementation is crucial for anyone working with automated systems. By appreciating the subtle power of this simple device, we can leverage its capabilities to create safer and more efficient processes across various industries. From industrial machinery to household appliances, the impact of these switches is often unseen but undeniably significant. They are the silent guardians of automation, ensuring that systems operate as intended, and providing a crucial layer of safety in our increasingly automated world.

Bathroom tile makeover can you tile over existing tiles

Ocean drive miami unveiled its location and vibe

Ocean city nj property taxes your guide to assessment records