Unlocking ATV Performance: Your ATV Wheel Bolt Pattern Guide

Ever wondered why your ATV’s wheels fit so perfectly? The answer lies in the often-overlooked ATV wheel bolt pattern. This crucial configuration dictates compatibility and ensures a safe and stable ride. Ignoring this seemingly minor detail can lead to disastrous consequences, from wobbly wheels to complete wheel detachment. This guide will delve into the world of ATV wheel bolt patterns, equipping you with the knowledge to make informed decisions and keep your off-road adventures safe and exhilarating.

Choosing the correct wheels for your ATV is more than just picking a style you like. It’s about ensuring a secure connection between your vehicle and the terrain. The ATV wheel bolt configuration, also known as the bolt circle or PCD (pitch circle diameter), is the precise arrangement of the bolt holes on the wheel hub. Understanding this pattern is paramount for safe and optimal ATV performance.

The history of wheel bolt patterns is intrinsically linked to the evolution of wheeled vehicles. As vehicles became more sophisticated, the need for standardized and interchangeable parts grew. This led to the development of various bolt patterns, each designed to provide specific performance characteristics and accommodate different wheel sizes and weights. For ATVs, the bolt pattern is especially critical given the challenging terrains and stresses these vehicles endure.

The importance of the correct ATV bolt pattern cannot be overstated. A mismatched pattern can lead to wheel slippage, vibration, and even complete wheel failure. This not only compromises your safety but also affects handling and performance. Imagine navigating a tricky trail with a loose wheel – a recipe for disaster. Therefore, knowing your ATV's specific bolt pattern is essential for safe and enjoyable off-roading.

One of the main issues related to ATV wheel bolt patterns is incorrect identification. Many ATV owners are unaware of their vehicle’s specific pattern, leading to potential compatibility problems when purchasing new wheels. This can be easily avoided by consulting your owner's manual or measuring the bolt pattern yourself. We'll cover how to do this later in the guide.

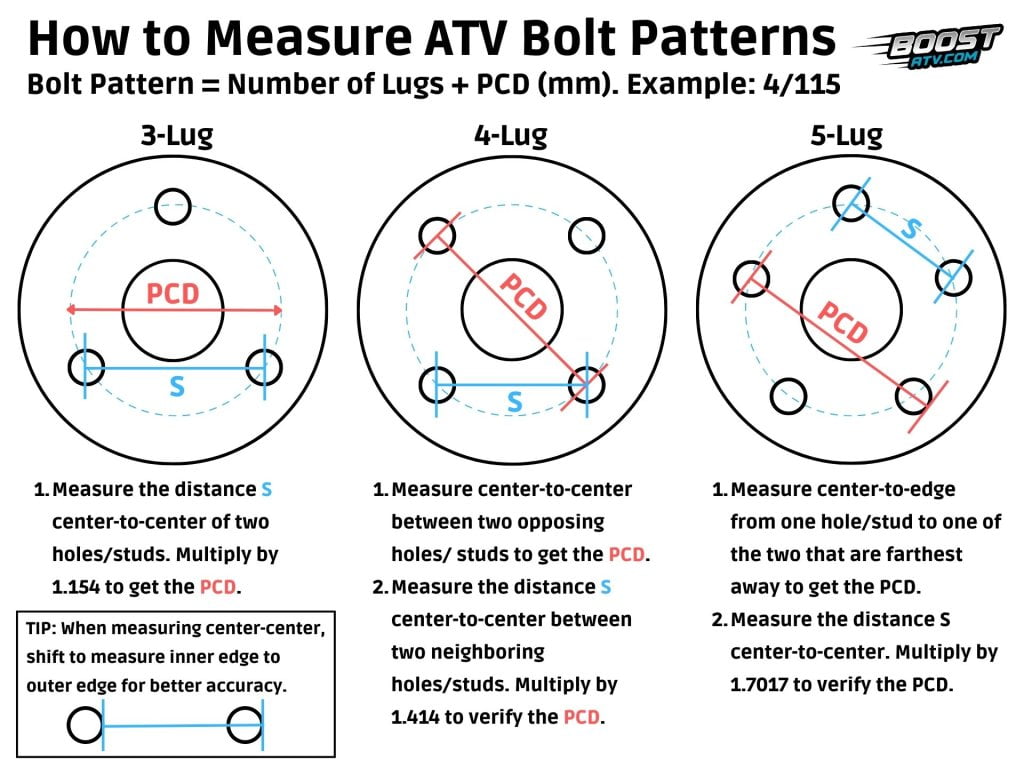

The ATV wheel bolt pattern is defined by two numbers: the number of bolts and the diameter of the circle on which the bolts are located. For instance, a 4/110 pattern signifies 4 bolts arranged on a circle with a diameter of 110mm. Understanding this nomenclature is the first step towards ensuring correct wheel fitment.

One benefit of knowing your ATV wheel bolt pattern is enhanced safety. Correct fitment prevents wheel detachment, ensuring a secure and stable ride. Another advantage is improved performance. A properly fitted wheel improves handling and reduces vibration, allowing for a smoother and more controlled ride. Finally, understanding your bolt pattern simplifies the process of purchasing new wheels. You can easily identify compatible options, saving you time and potential headaches.

To determine your ATV's wheel bolt pattern, you'll need a ruler or caliper. For 4-bolt patterns, measure from the center of one bolt hole to the center of the opposite bolt hole. For 5-bolt patterns, measure from the back of one bolt hole to the center of the bolt hole two positions away. This measurement corresponds to the PCD.

Best practices include always double-checking the bolt pattern before purchasing new wheels, consulting your owner's manual for specific recommendations, and having a professional install your new wheels to ensure proper torque and fitment.

Advantages and Disadvantages of Standardized ATV Wheel Bolt Patterns

| Advantages | Disadvantages |

|---|---|

| Wider selection of compatible wheels | Limited customization options for unique fitments |

| Easier to find replacement wheels | May not be optimal for all performance applications |

Common ATV wheel bolt patterns include 4/110, 4/137, and 4/156. Examples of ATVs with these patterns include the Honda TRX450R (4/110), Yamaha Raptor 700 (4/115), and Polaris Sportsman 570 (4/156).

Challenges related to ATV wheel bolt patterns include difficulty in measuring patterns on older or damaged wheels and the availability of less common patterns. Solutions include consulting online forums or contacting a specialized ATV parts supplier.

FAQ: What is a wheel bolt pattern? How do I measure it? What are common ATV bolt patterns? What happens if I use the wrong bolt pattern? Where can I find my ATV's bolt pattern? What are the different types of wheel lugs? How do I choose the right lug nuts? What is wheel offset?

General answers provided for each question.

Tips and tricks: Use a digital caliper for precise measurements. Clean the hub surface before mounting new wheels. Always torque lug nuts to the manufacturer's specifications.

In conclusion, understanding your ATV wheel bolt pattern is crucial for safety, performance, and overall enjoyment of your off-road adventures. From ensuring proper wheel fitment to preventing potentially dangerous situations, knowing this seemingly small detail can make a world of difference. By following the guidelines outlined in this guide, you can confidently select compatible wheels, maintain optimal ATV performance, and enjoy countless miles of thrilling off-road experiences. Take the time to identify your ATV's bolt pattern, consult your owner's manual, and seek professional advice when needed. Your safety and the longevity of your ATV depend on it. Don’t underestimate the importance of this critical component – master your ATV wheel bolt pattern and unlock the true potential of your off-road machine. Remember, a well-informed rider is a safe and confident rider.

Unlocking serenity exploring sherwin williams rainwashed colors

The curious case of the microsoft azure water bottle

Aniwatch continue watching feature troubleshooting