Unlocking the Secrets of the Float Switch Electrical Diagram

Imagine a world without automatic water level control. Think overflowing tanks, burnt-out pumps, and constant manual monitoring. Sounds chaotic, right? Thankfully, we have a clever little device called a float switch to prevent this watery mayhem. But what exactly *is* a float switch, and how does it work its magic? More importantly, how can we decipher its electrical representation, the float switch electrical diagram? This is where our journey begins, exploring the fascinating world of these unsung heroes of liquid level management.

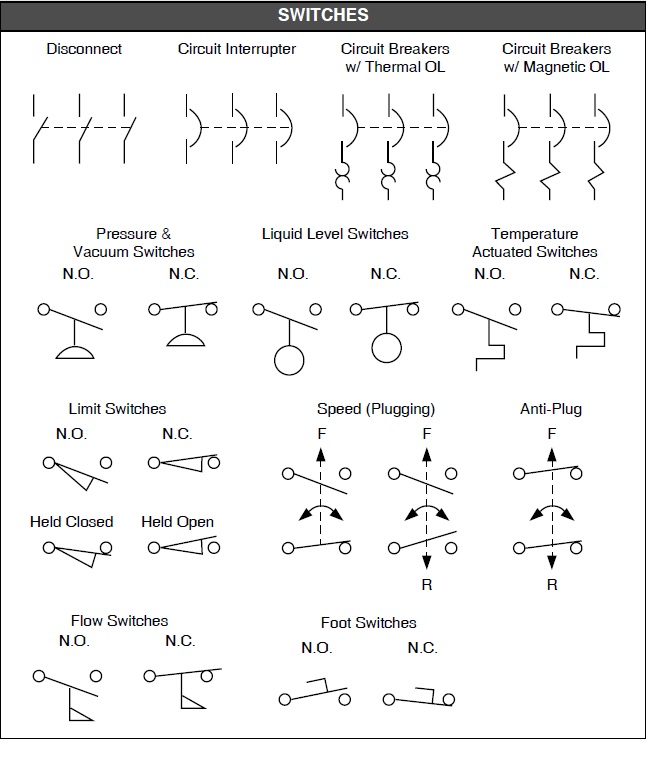

The float switch electrical symbol, a seemingly simple diagram, holds the key to understanding how these devices integrate into larger electrical systems. It's the shorthand that electricians and engineers use to communicate the function and connection points of the float switch. This symbolic language allows for efficient design and troubleshooting, ensuring that our water tanks stay full, our sump pumps kick in when needed, and our industrial processes run smoothly.

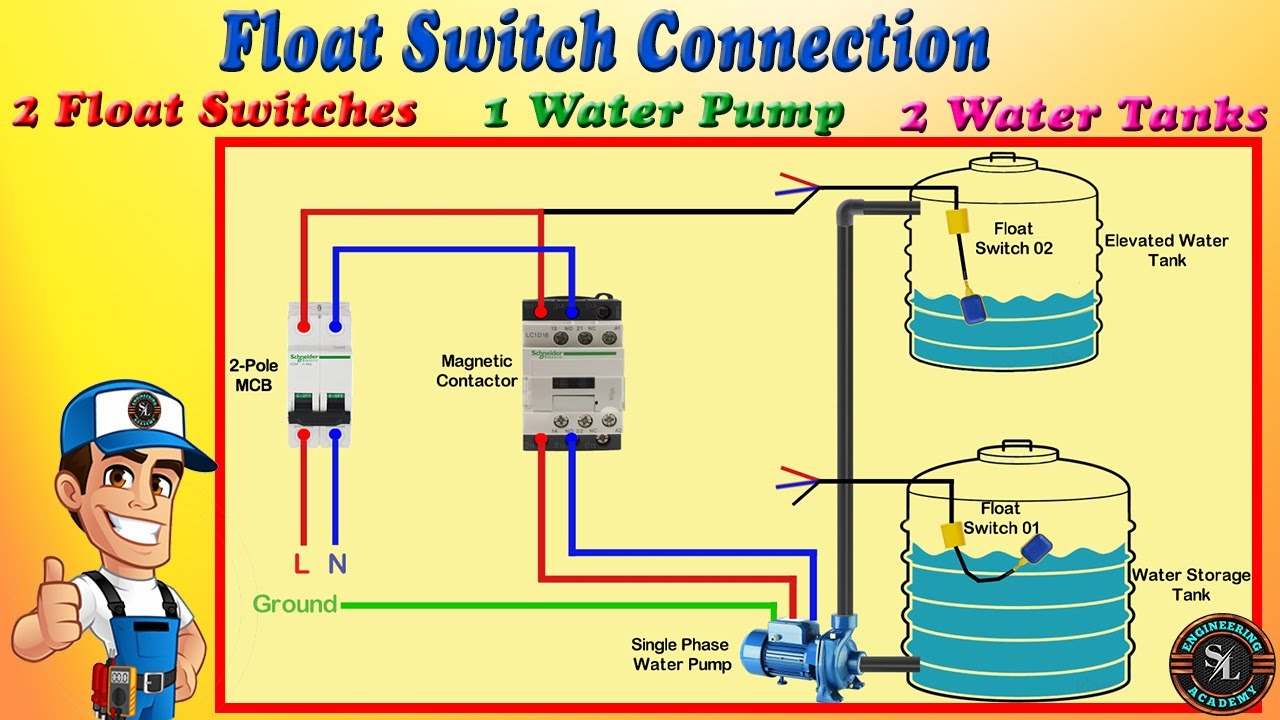

Essentially, a float switch is a level sensor. It detects the level of liquid within a tank or container and uses this information to trigger a switch. This switch, in turn, can control pumps, valves, or alarms, automating the entire liquid management process. Think of it as a tiny lifeguard for your water systems, constantly vigilant and ready to take action when the water level gets too high or too low. But how does it translate this physical movement into an electrical signal? That’s where the float switch wiring diagram comes into play.

The core of a float switch is its buoyancy. A sealed, buoyant float rises and falls with the liquid level. This movement is mechanically linked to a switch mechanism. As the float reaches a certain level, the switch is activated, sending an electrical signal. The float switch schematic illustrates the various configurations of these switches, including normally open (NO) and normally closed (NC) types, allowing for diverse control options.

Understanding the float level switch symbol is crucial for anyone working with these devices. It provides a visual representation of how the switch operates within a circuit, including the connections for power, the controlled device (like a pump), and the switching mechanism itself. This understanding is fundamental for proper installation, wiring, and troubleshooting, ensuring the safe and efficient operation of your liquid level control systems.

The precise origin of the float switch is somewhat obscure, lost in the annals of engineering history. However, the basic principles of buoyancy and mechanical switching have been understood for centuries. The modern float switch, with its reliable electrical components and diverse applications, is a testament to the continuous refinement of these fundamental concepts.

The float switch schematic typically depicts the float, the switch mechanism, and the electrical connections. Variations in the symbol indicate the type of switch, such as normally open or normally closed. These diagrams are essential for interpreting wiring diagrams and understanding the functionality of the float switch within a circuit.

Benefits of using a float switch include automated liquid level control, prevention of overflows and dry-run conditions for pumps, and improved system efficiency. For example, in a sump pump application, a float switch automatically activates the pump when water reaches a certain level, preventing basement flooding.

To install a float switch, first determine the desired switching point and mount the switch accordingly. Then, connect the electrical wires according to the wiring diagram, ensuring proper grounding. Finally, test the system to verify correct operation.

Advantages and Disadvantages of Float Switches

| Advantages | Disadvantages |

|---|---|

| Automated Control | Limited to liquid level sensing |

| Simple Operation | Potential for mechanical failure |

| Cost-Effective | Sensitivity to turbulence |

Best practices for implementing float switches include selecting the correct type of switch for the application, ensuring proper wiring and grounding, and regularly inspecting and maintaining the switch.

Real-world examples of float switch applications include sump pumps, water tanks, sewage systems, and industrial process control.

Challenges related to float switches can include turbulence, debris buildup, and corrosion. Solutions can involve using specialized float designs, regular cleaning, and selecting materials resistant to the specific environment.

Frequently Asked Questions:

1. What is a float switch? - A device that senses liquid level and activates a switch.

2. What is a float switch electrical symbol? - A diagrammatic representation of the switch in a circuit.

3. How does a float switch work? - Uses buoyancy to activate a switch based on liquid level.

4. What are the different types of float switches? - Normally open, normally closed, and others.

5. Where are float switches used? - Sump pumps, tanks, industrial processes.

6. How do you wire a float switch? - Refer to the wiring diagram specific to the switch and application.

7. What are the benefits of using a float switch? - Automation, overflow prevention, efficiency.

8. How do you maintain a float switch? - Regular inspection and cleaning.

Tips and tricks for using float switches effectively include ensuring proper mounting to avoid false triggering, using appropriate wiring techniques for reliable operation, and choosing materials compatible with the liquid being monitored.

In conclusion, the float switch, a seemingly simple device, plays a crucial role in countless applications, from managing our household water systems to controlling complex industrial processes. Understanding the float switch electrical symbol, its variations, and its representation within circuit diagrams is fundamental for anyone working with these devices. Proper installation, wiring, and maintenance are essential for maximizing the benefits of float switches, ensuring reliable and efficient liquid level control. By mastering these concepts, we can harness the power of these ingenious devices to automate our systems, prevent costly damage, and contribute to a smoother, more efficient world. By embracing the versatility and simplicity of float switches, we can create more robust and reliable liquid management systems for a wide range of applications. From protecting our homes from flooding to optimizing industrial processes, the float switch remains a vital component in our modern world. Its simple yet effective design, coupled with a clear understanding of its electrical representation, empowers us to control and manage liquids with precision and ease.

Unlocking roblox a guide to pls donate stand codes

Find fedex drop off locations near you

Unleash your inner sensei exploring the world of manga with master disciple dynamics